Research Article

Volume 6 Issue 1 - 2024

Artificial intelligence (AI)/ML in Packaging innovations for Drug Discovery

B.Sc(Math), MS in Packaging and Polymer Science Technologist, Bioxytran Inc, MA, Boston, USA

*Corresponding Author: Anupam Chanda, B.Sc(Math), MS in Packaging and Polymer Science Technologist, Bioxytran Inc, MA, Boston, USA.

Received: December 24, 2024; Published: December 31, 2024

Abstract

Artificial intelligence (AI) is a technology that enables computers and machines to simulate human learning, comprehension, problem solving, decision making, creativity and autonomy. AI software can perform a variety of tasks, including: Content generation, Data analysis, Prediction, Process automation, Decision-making, Learning, and Problem-solving. ML/AI can help vision system experts to identify and sort false ejects from large image data sets for oral, Injectables, solids, semi-solid Doses form products “ONLINE INSPECTION”.

Following software are mostly using in AI &ML :

(1) Python- Software integration with AI/ML :

(1) Python- Software integration with AI/ML :

- Python is widely used in AI due to its simplicity, versatility.

- Rich selection of libraries for machine learning and data analysis.

- It allows developers to create intelligent systems that can learn from data, recognize patterns, and make decisions.

- Possibilities in computer vision applications.

- Enhanced object detection to sophisticated image recognition.

- Facilitates tasks like image classification, object detection, and video analysis through easy-to-implement convolutional neural networks (CNNs).

- Ideal for applications from medical imaging diagnostics to automated manufacturing quality control.

- Natural language processing

- Computer vision

- Object detection

- Exact recognition

Steps to Follow:

- Data collection from Existing Vision inspection machine

- ML/AI can help vision system experts to identify and sort false ejects from large image data sets.

- ML/AI can facilitate a streaming analytics platform for the automated vision inspection process. This streaming analytics platform will support the vision system experts with rapid identification and remediation of both true and false ejects from the upstream drug product unit operations.

- Vision inspection team collaborate with the data science team to develop a prototype convolutional neural network (CNN) to test the ability of AI/ML models to identify true versus false ejects.

- After the eject- and acceptable-image sets had been assembled, the team collaborate with data science team to develop a deep learning model that could classify the images using Python, Open CV, Keras, and Tensor Flow.

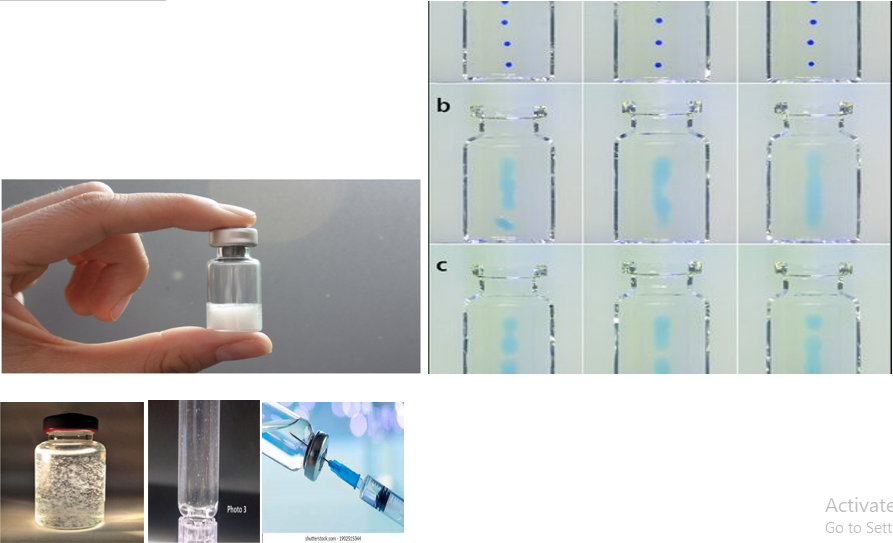

AI ensures Precision in Vial & PFS Inspection

- Maintaining rigorous quality control standards when mass-producing vials of liquid medicine can be challenging.

- Vials can be subject to contaminants,or cross-contamination can occur during manufacturing. These “defects” cannot be tolerated.

- Detecting these issues is nearly impossible for the human eye, especially when vials are produced at a high rate.

Deep Learning and Edge Learning in Pharmaceutical Inspection

AI's revolutionary potential lies in deep learning and Edge learning.

AI's revolutionary potential lies in deep learning and Edge learning.

Deep learning

- This technology predict patterns and perform judgment-based applications.

- Deploys artificial intelligence (AI) algorithms to teach robots and machines to do what comes naturally to humans: learning by example.

- Advanced manufacturing practices for quality inspection and task automation.

- Deep learning technology transfers the logical burden from an application developer, who develops and scripts a rules-based algorithm, to an engineer training the system. In this way, deep learning makes machine vision easier to work with, while expanding the limits of accurate inspection.

Edge learning

- Deploying AI models directly on the production line equipment.

- Provides real-time data analysis and decision-making.

- Significantly reducing inspection time.

- Enhancing overall efficiency.

Silicone Oil Induced Effects in Pharmaceutical Glass Vials

Manual Inspection

Manual Inspection

Visual inspection Display Panel:

Particle inspection in liquid product

Advantages to use AI for online inspection for Injectables:

- Most of the cases this has been observed in manual inspection, it is not possible to find out and eject very small silicon oil drops and silica flex and such kind of products are not ejected from the packing line. AI/ML can solve these problems online within fraction of seconds.

- Very small back particles, glass particles, rubber stopper loose parts AI can identify and ejected those vials/PFS from packing line.

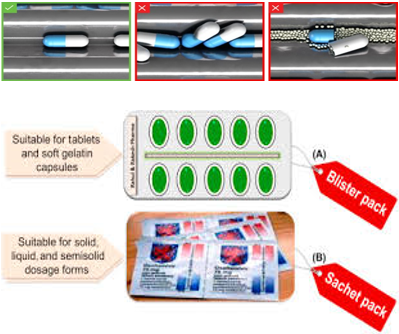

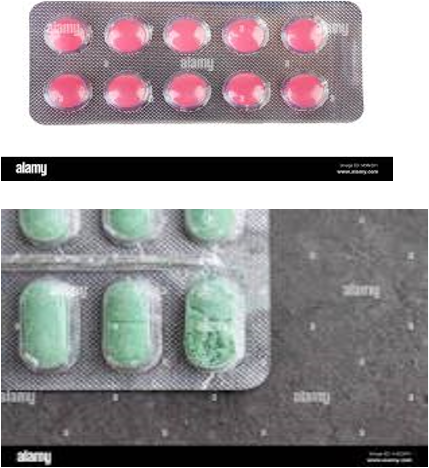

AI and ML for Solid doses Form

Empty pocket and Black dots in Tablets

Color shade difference & Broken Tablets

Advantages to use AI for online inspection for solid Doses:

- In high speed blister packing line, empty pockets, black dots, broken tablets, dented capsules, open caps, out of range coloured tablets not possible to identify 100% online. AI/ML can solve such problems and avoid market complaints.

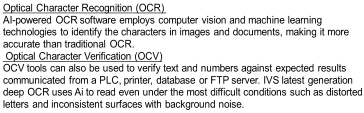

Label and Lot Code Verification with OCR and OCV

Advantages to use AI/ML for Batch coding Inspection

- Missing of words in text, scratch on text, improper batch coding, 2D data matrix is not proper, colour share of label and carton are not proper such kind of defective packaging materials are not possible to eject from the packing line. AI/ML can do this activities perfectly and avoid market complaints.

AI applications in Microgravity Environments in Packaging Design

Single bubble in the syringe can spoil the Eye

Cardiac problem on space station

High Radiation in Microgravity

Gold Foil Coated Vial & PFS to prevent high Radiation

Bubble Free Injection Syringe in Space a Big Challenge

Author’s Biobraphy:

Post Graduate Packaging and Polymer Scientist having 30 years experience in reputed Pharmaceutical companies in USA, Germany, Singapore, India etc.

- Visiting lecturer in IIP, Mumbai, India.Extensive hand on experience in “ Injectable DEVICES”

- Done research in wide range of “ Polymers and it’s applications in different Pharmaceutical products.

- International speaker for last 15 years. Delivered lecture in Boston, USA, Italy, Germany, France, Singapore and many places in India.

- Written “Three Technical Books”, published from Germany.

- “Packaging Innovation for Microgravity Book” is considered as Reference book in “ Harvard University, USA”

- Packaging Technology An advance Practical Approach” this book is also considered as a Reference book in Indian Institute of Packaging, India.

- “Regulatory Audit observations and Responses. Last four years doing “Consulting” activities in USA. Already published more than 30 Articles in USA and Europe based reputed Journals.

References

- Artificial Intelligence (AI) Applications in Drug Discovery and Drug Delivery: Revolutionizing Personalized Medicine

- In Space Production: Applications Within Reach.

- Artificial Intelligence in Pharmaceutical Sciences

Citation: Anupam Chanda. (2024). Artificial intelligence (AI)/ML in Packaging innovations for Drug Discovery. Journal of Pharmacy and Drug Development 6(1).

Copyright: © 2024 Anupam Chanda. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.